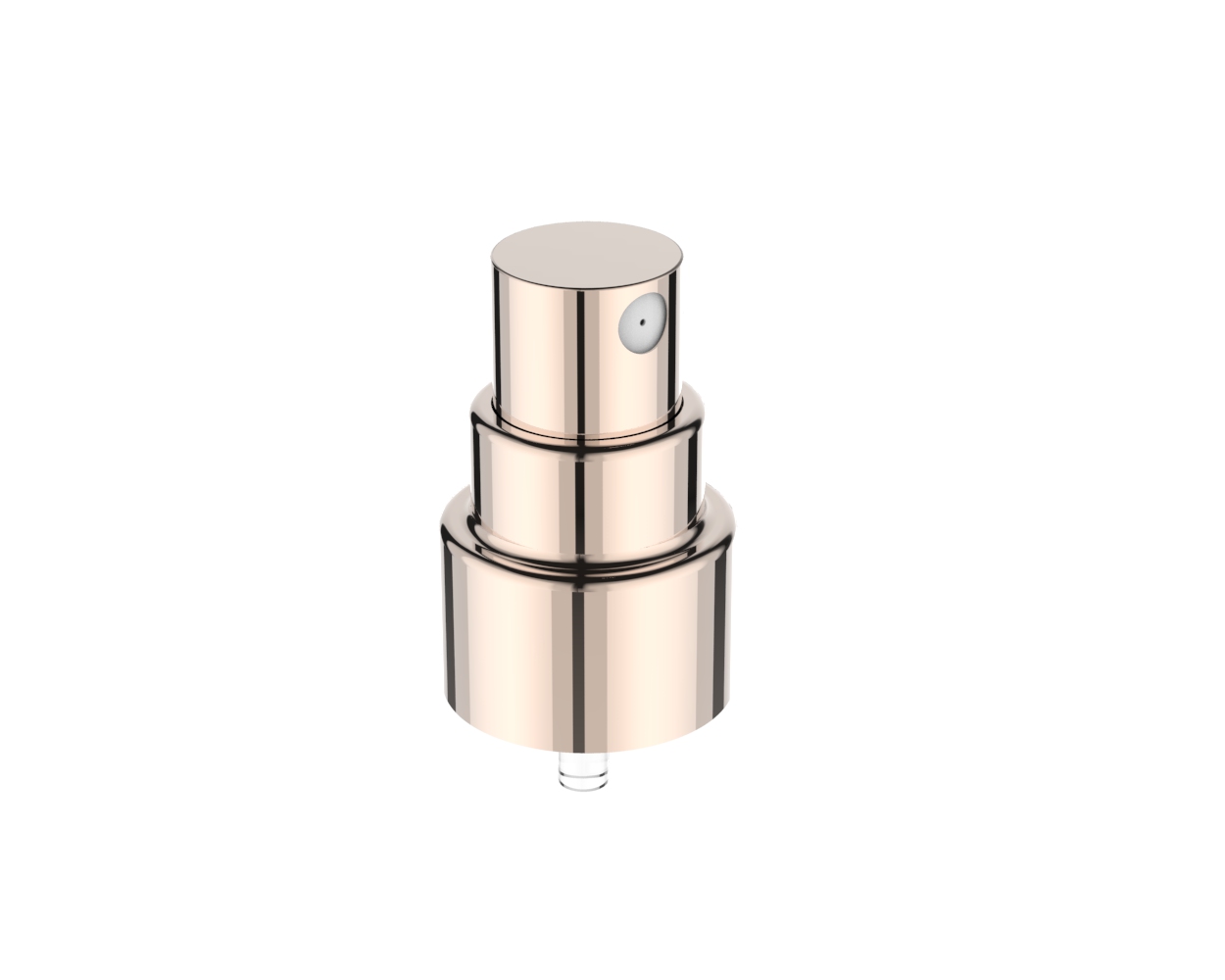

We know that cosmetic pump head is divided into quantitative pump and aerosol pump, and these pumps to achieve normal work should have the following eight functional structure.

Discharge channel

Generally constitute the channel parts have pressure head, eye, foam pump will have a screen tube. The material body in the container by the pump core role, to reach the container outside the channel, this part will determine the material body spitting state, is fog, liquid or foam.

Suction channel

The material in the container through the pump core action into the cylinder body before the passage.

The parts that constitute the channel are generally connected to the end of the cylinder suction tube, for the vacuum pump is no suction tube, by the container of the large piston continues to rise or soft container contraction to ensure that the material body continues to contact the cylinder tail hole.

Pump material system

The general components of the cylinder, piston, ball valve, connecting rod and plug sleeve (lock cover). Piston in the role of force, in the cylinder body to do reciprocal movement, set in the pump body before and after the two ends of the valve structure will be sequentially open and closed, the container material body in the role of pressure difference, from the suction channel into the pump body and through the material channel to reach the container outside the process is a number of parts to complete the system action. The parts that constitute the system are generally cylinders, pistons, valves, connecting rods, plug sleeve, and the power mechanism with the composition.

Power mechanism

The piston needs to be under the action of force to do reciprocating motion in the cylinder, the source of power for the downward pressure stroke is applied by the user outside, so that the upward pressure rod its drive piston to overcome the spring force and the friction between the piston and the cylinder downward motion, when the user releases the external force, the piston under the action of spring force, reverse motion. The main parts that constitute the body of the mechanism for the upper pressure rod, spring, which must be attached to the cylinder and other parts of the structure as a substrate to act.

Convection channel

The material is constantly spit out from the container to the container outside, the volume occupied by the spit out material must constantly have air into the supplement to ensure that the pressure is constant, the pump head can continue to work.

Anti-opening structure

For unintended open the role of the prohibition.

In order to prevent the material body before delivery to the consumer use, including packaging, handling, transportation and other processes, the pump head occurs in the non-expected pressure caused by the material body spitting out, the pump head must be done to prevent the opening of protection. The same function commonly used structure: cover (cover) protection, clip (buckle) protection, thread protection, directional opening protection and other anti-pressure protection structure.

Linking parts

Make the pump and the container to do effective connection parts. The general composition of the parts have screw cap, card cover, and with a tightening piece to ensure air tightness.

Auxiliary accessories

To play a decorative role, some are also part of the structure. Commonly used structures are: pressure head aluminum sleeve, pressure head plastic sleeve, screw cap aluminum sleeve, screw cap plastic sleeve, etc.