Cosmetics as the messenger of beauty, is taking care of more and more people, whether it is a vibrant young girl or a peaceful and peaceful woman, all dear to cosmetics, can not help but love.

Cosmetics booming today, the cosmetic companies pay considerable attention to improving the quality of the product, for the development of the internal material formula since is very concerned about, at the same time for the cosmetic carrier ---- package material upgrade is also spared no effort. With the increasing demand for more convenient use and safer protection of cosmetics, pumps are increasingly being used as the optimal solution for each cosmetic product line.

There are many different pumps on the market, with different sizes, shapes, spitting states, etc. So what is the working principle of so many pumps? Is there any commonality between them?

Two categories of cosmetics pump

- quantitative pump: the power to make the material spit out from the outside, usually by hand pressure.

- aerosol pump: the power to make the material spit out from the internal, need to add pressure gas while filling the aerosol cans in the appropriate material.

The two major categories of pumps differ in their functional structure due to different power sources.

Quantitative pumps are divided into spray pumps, emulsion pumps, foam pumps according to the state of exhalation; according to the applicable products can be divided into: fragrance water pumps, vacuum pumps, foam pumps, etc. Today we mainly introduce the external pump and built-in pump of cosmetic pump head.

Differences and applications of cosmetic built-in pump and external pump

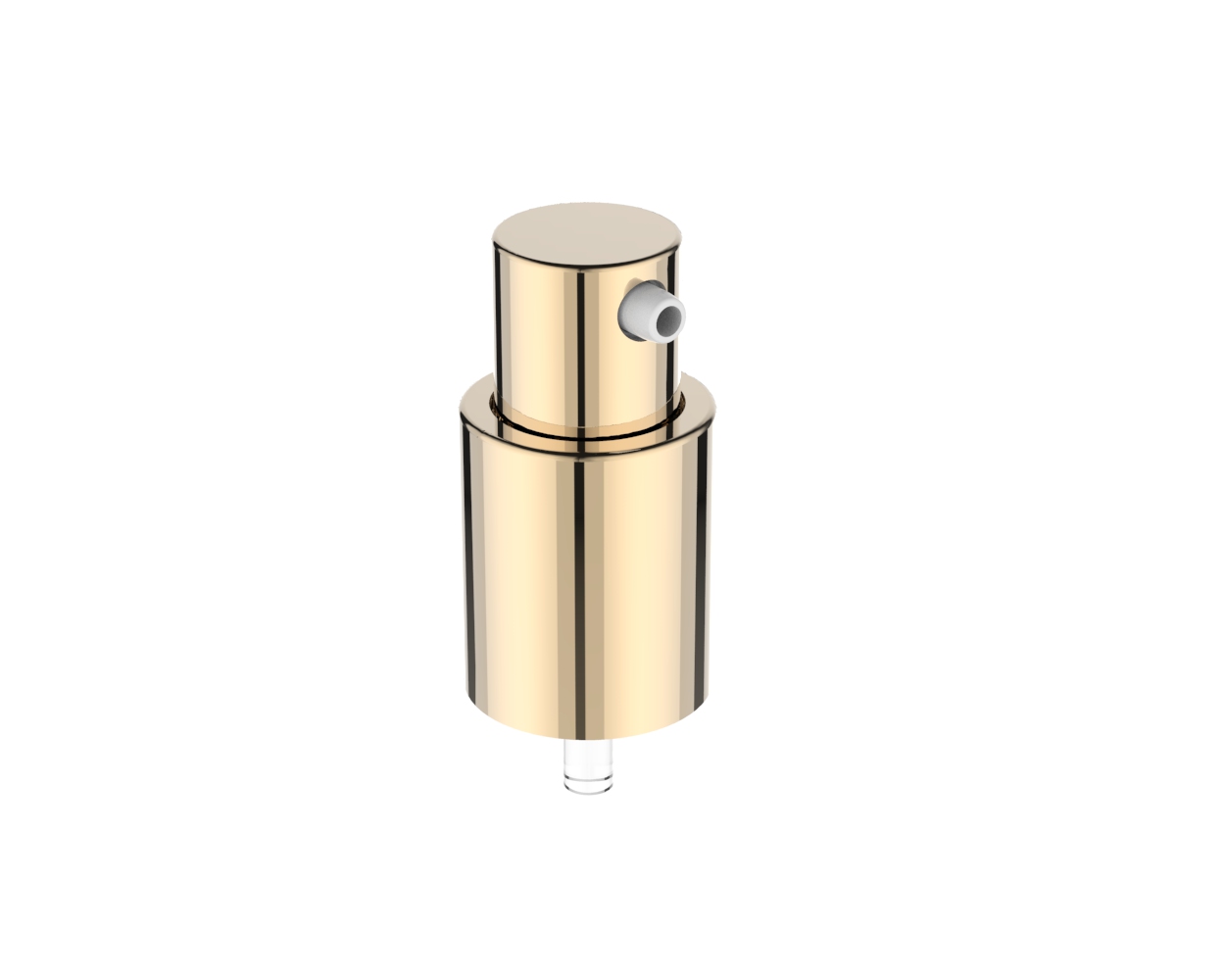

External pump: for the nozzle and pump head of this type, we should all know that in the center of the product is required to place the spring inside it, external pump that the nozzle / pump head center spring is external visible, generally placed above the pump core, assembly is directly connected to the nozzle / pump head cap. The advantage of the external pump is not in direct contact with the liquid inside the bottle, both environmental health, but also 100% to avoid individual spring rust, affecting the quality of the product inside the bottle, of course, this problem is very rare, because most of the spring is treated. In addition, the force of the external pump is relatively larger than the built-in pump, so the general pump head with external pump more, for the original lotion, which is a more viscous liquid.

Built-in pump: the opposite of the external pump, the built-in pump that nozzle / pump head center spring is built-in not visible, generally located in the middle of the pump body, the internal spring is directly accessible to the liquid, according to the pressure channel is slightly smaller than the external pump, generally used in health care products essential oils and perfumes and skin care water and water closer to this category.

The above is a brief introduction to the common cosmetic pump head. For more information about cosmetic pump heads, please feel free to contact us, we are happy to serve you!