1/4

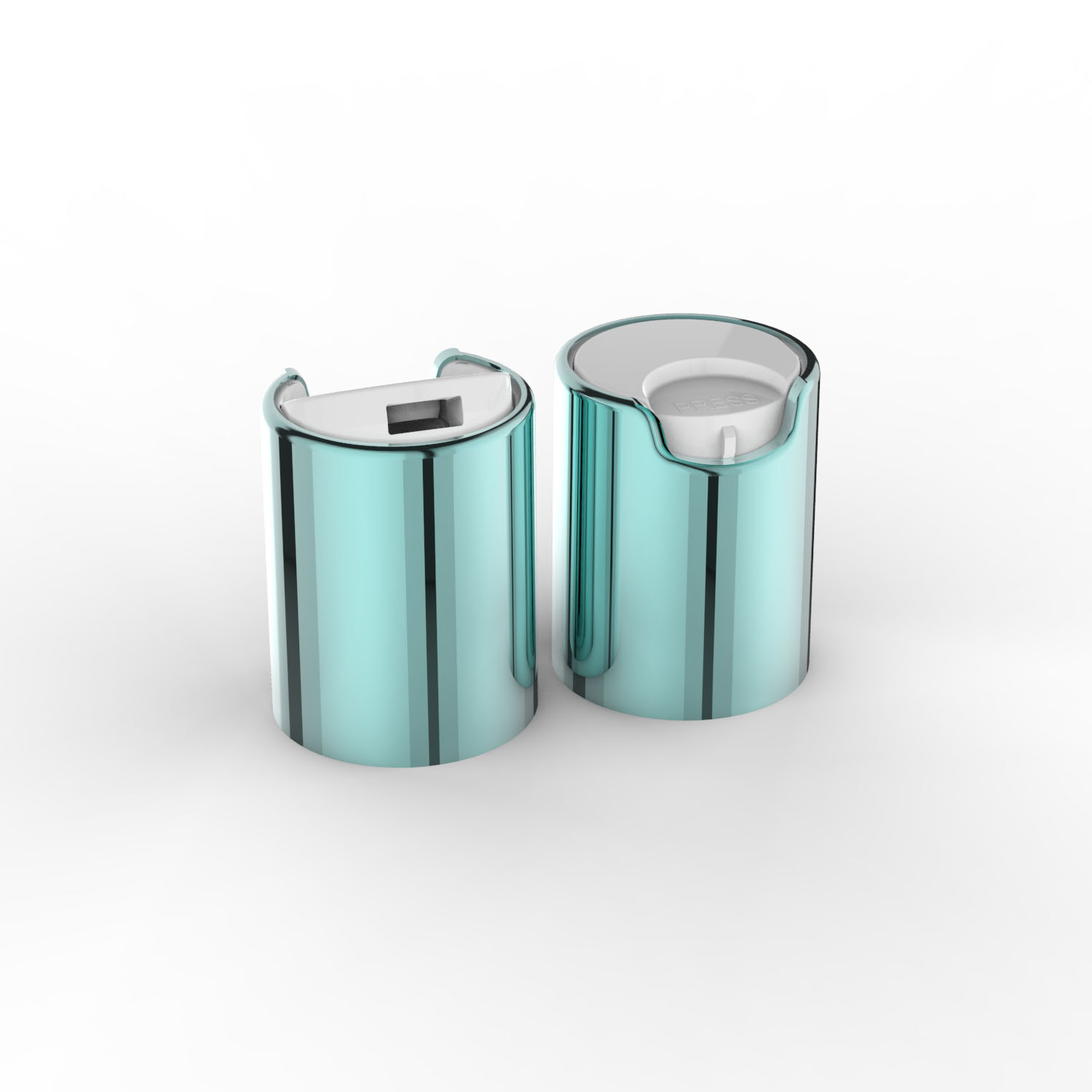

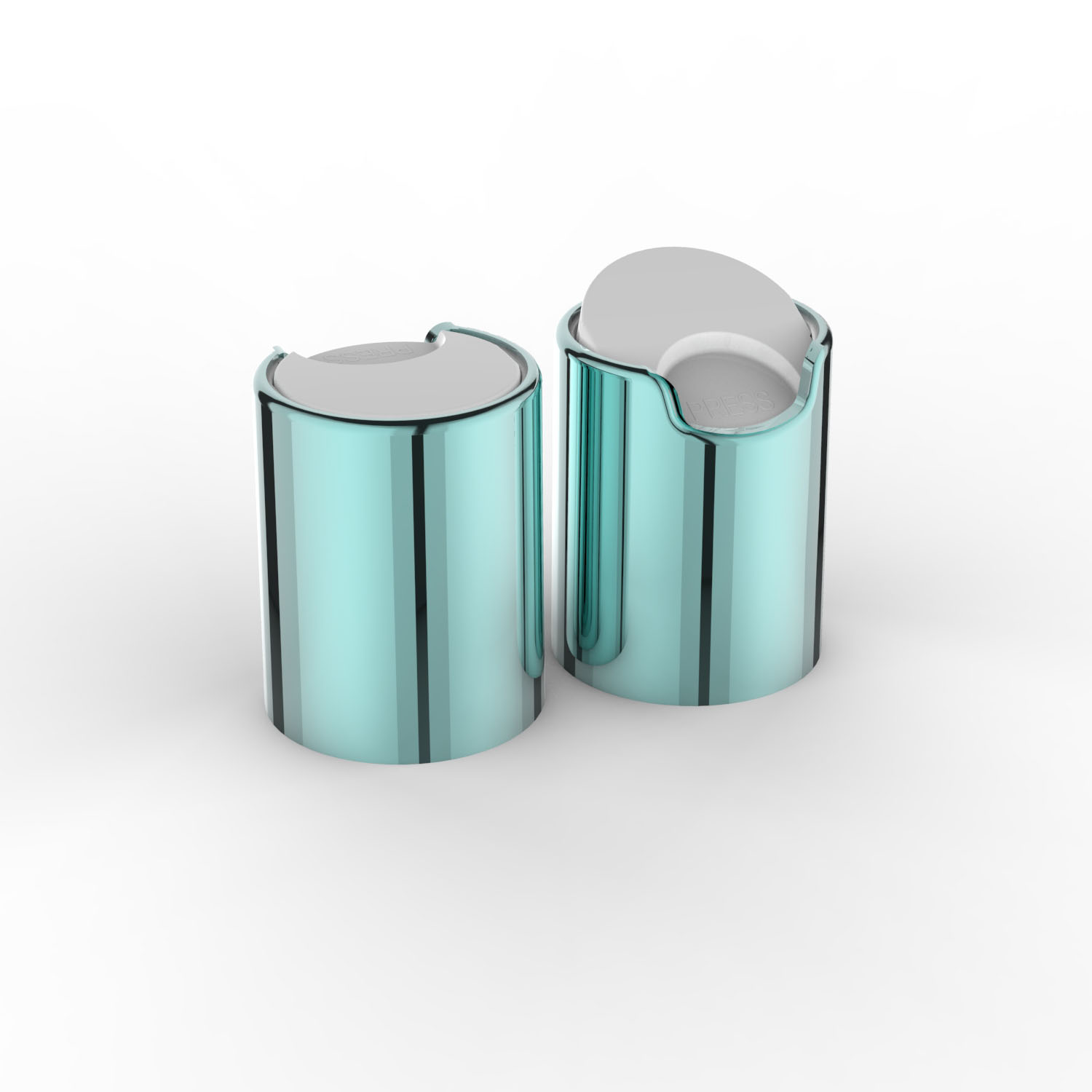

Shiny gold disc top cap screw top bottle cap | PH-243A 24/410

Quick Details

Product Code:

PH-243A 24/410

OEM:

Available

Sample:

Available

Payment:

T/T

Place of Origin:

China

Supply Ability:

10000 piece per week

Quick Details

Shipping fee

Shipping fee

| Material: | Aluminum outer+pp inner |

| Type: | Disc cap |

| Usage: | Bottles |

| Feature: | Non Spill |

| Custom Order: | Accept |

| Place of Origin: | Guangzhou, China |

| Brand Name: | Lihua |

| Model Number: | PH-243A |

| Product name: | Shiny gold disc top cap screw top bottle cap |

| Size: | φ28.49*28.96 |

| Closure Color: | Silver,gold,black or customized |

| Neck size: | 24/410 |

| MOQ: | 10000pcs |

| Packing: | PVC Tray+Carton+pallet |